What is Electromagnetic Compatibility (EMC)?

Electromagnetic compatibility can be defined as any type of effect that does not produce electromagnetic interference in the case of the generation, transmission, and reception of electromagnetic energy. As a result of the standard, electromagnetic compatibility has become a very important criterion for the marketing of electronic products. If a product does not meet the electromagnetic compatibility requirements of any country, the product may not be sold in that country. Due to the development of technology, electromagnetic compatibility in electronic equipment or system design has become as important a design criterion as other traditional design criteria.

EMC connotation

EMC consists of two major items: EMI(interference) and EMS(susceptibility).

EMI test items include:

RE (radiated, emitted), CE (conducted interference), Harmonic (harmonic), Flicker (flickering)

EMS test items include:

ESD (Electrostatic), EFT (Transient Pulse Interference), DIP (Voltage Dip), CS (Conducted Immunity), RS (radiation immunity), Surge (surge, lightning strike), PMS (power frequency magnetic field immunity)

As mentioned above, EMC includes two major test items: EMI and EMS. The key point of EMI verification is the amount of electromagnetic energy radiated by the electrical appliance itself during operation. The greater the energy, the greater the possibility of interfering with other electrical appliances. The energy of electromagnetic radiation should be suppressed at as lower a level as possible, and the limit values of various standards can be drawn in the verified spectrum, which is helpful for judging whether there is a risk of exceeding the limit value during the operation of the electrical device.

In contrast, the verification focus of EMS is on the electromagnetic immunity of the electrical appliance itself, and also on its anti-interference ability, whether there is a risk of malfunction when operating together with other electrical appliances, so the electromagnetic energy is continuously fed into the operation. In the test object, observe whether the test object occurs or how much electromagnetic interference environment produces unexpected malfunctions.

The verification items of system integration products in the standard series are EMI Pre-scan (including radiated RE & conducted CE). Therefore, the sharing of actual cases below this article takes RE as an example to illustrate.

The customized case is determined according to the customer’s needs. The projects tested by the example are Radiated RE, Conducted CE, Electrostatic ESD, and Electromagnetic Radiation Resistance RS. Due to the content of the customized case, no example sharing will be made.

Verification standards:

| Items | Applicable |

|---|---|

| EN 55014-1 | Home Appliance Radiation |

| EN 55014-2 | Radiated immunity of household appliances. |

| EN 55011 | Radiation from Industrial, Scientific, Medical Equipment |

| EN 55013/20 | Audio and video products |

| EN 55015 | Radiation from lighting appliances |

| EN 61547 | Radiated immunity of lighting appliances |

| EN 55022 | Radiation from Information Technology Equipment |

| EN 55024 | Radiated immunity of information technology equipment |

| EN 60601-1-2 | Electromagnetic compatibility of medical electronic equipment |

| EN 61000-6-1 | Emissions from general equipment used in residential, commercial, and light industrial environments |

| EN 61000-6-3 | Radiated immunity of general equipment for use in residential, commercial, and light industrial environments |

| EN 61326 | Electromagnetic compatibility of measuring instruments and equipment |

| IEC 61000-4-4-2004 | Electromagnetic compatibility Test and measurement techniques Electrical fast transient burst immunity test |

| IEC 61000-4-5-2005 | Electromagnetic Compatibility Test and Measurement Techniques Surge (Shock) Immunity Test |

| IEC 61000-4-11-2004 | Electromagnetic compatibility – Test and measurement techniques Immunity tests for voltage dips, short interruptions, and voltage variations |

| IEC 61000-4-2-2001 | Electromagnetic compatibility Test and measurement techniques Electrostatic discharge immunity test |

Example sharing: RE (Radiated Emission radiation interference test)

In a practical RE verification, electromagnetic radiation is divided into two modes: vertically polarized wave and horizontally polarized wave. The two modes can be verified by rotating the angle of the receiving antenna. After the antenna angle is set, turn on the DUT (Device Under Test) to make it work normally, and then rotate the DUT (Device Under Test) installation table 360 degrees to scan electromagnetic radiation at various angles.

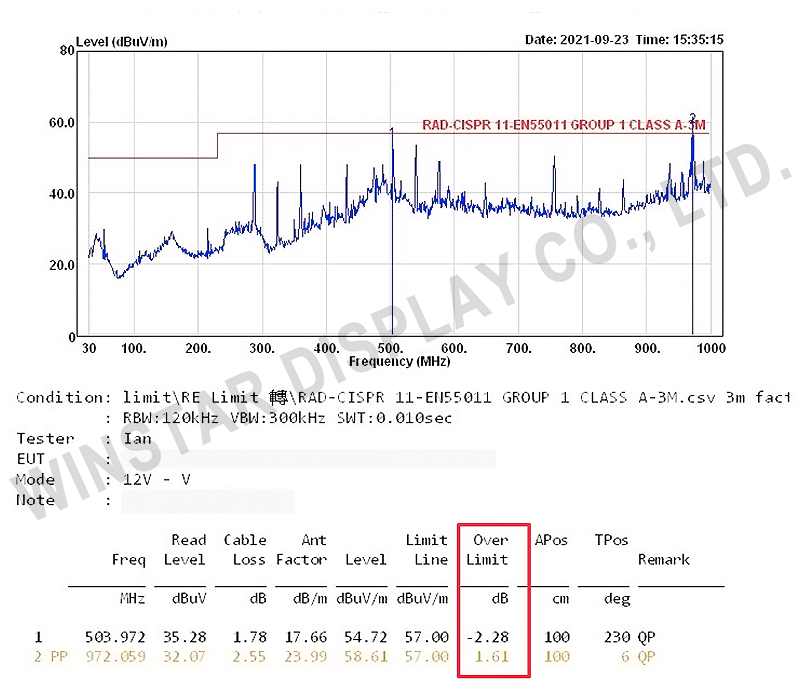

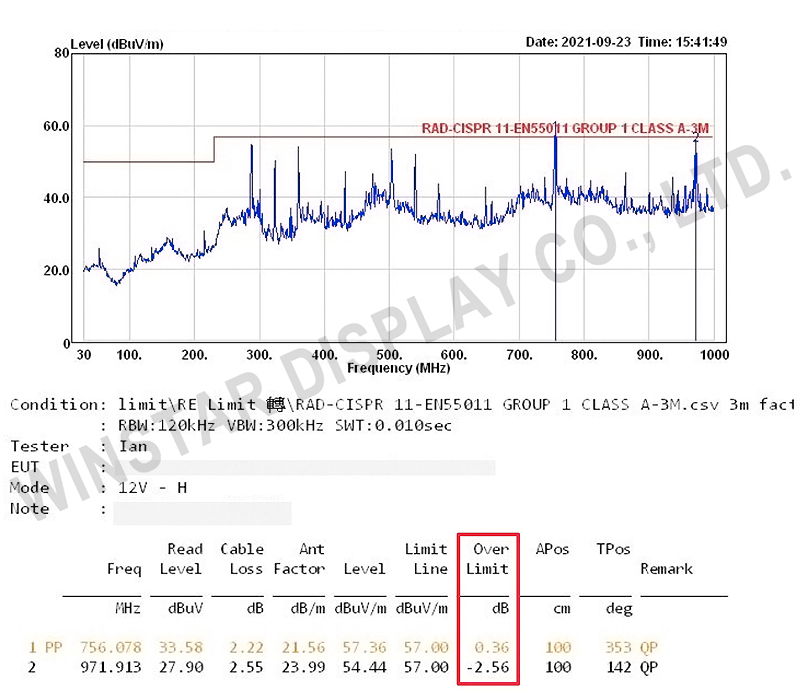

The following case is: In the early stage of the Smart Display 4.3-inch product design, it was found in Pre-Scan that the radiation exceeded the standard EN 55011 as follows:

Vertical

Horizontal

After the first EMI pre-scan, analyze the frequencies exceeding the limit value. From the figure, it can be found that 756MHz and 972MHz are the frequencies with higher radiation, and then find out the possible fundamental signal in the system from these frequencies. The signal might be the interference source; suppress the signal of the interference source as an EMI-suppressed solution.

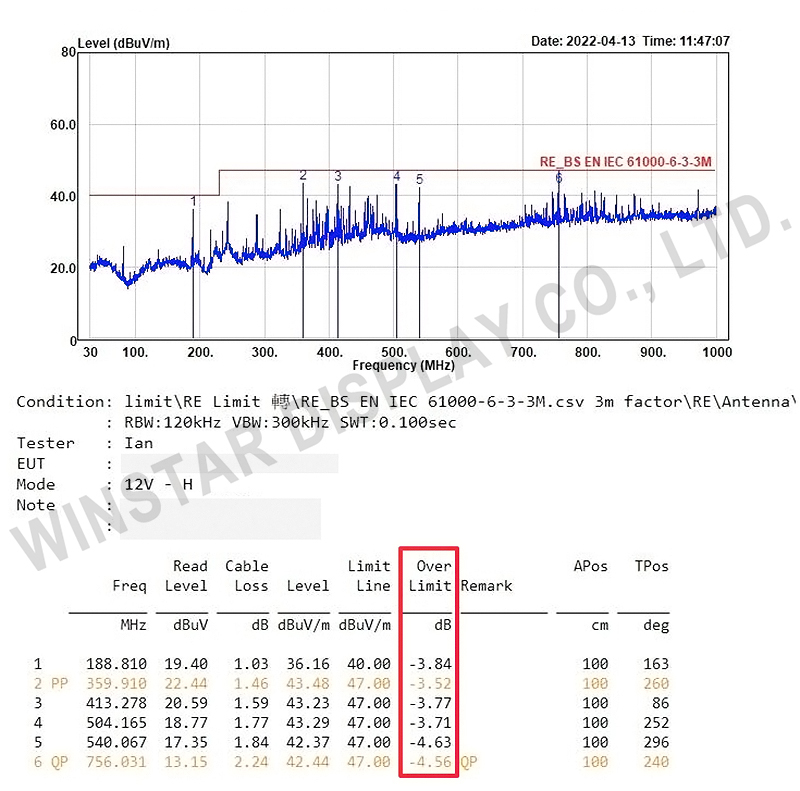

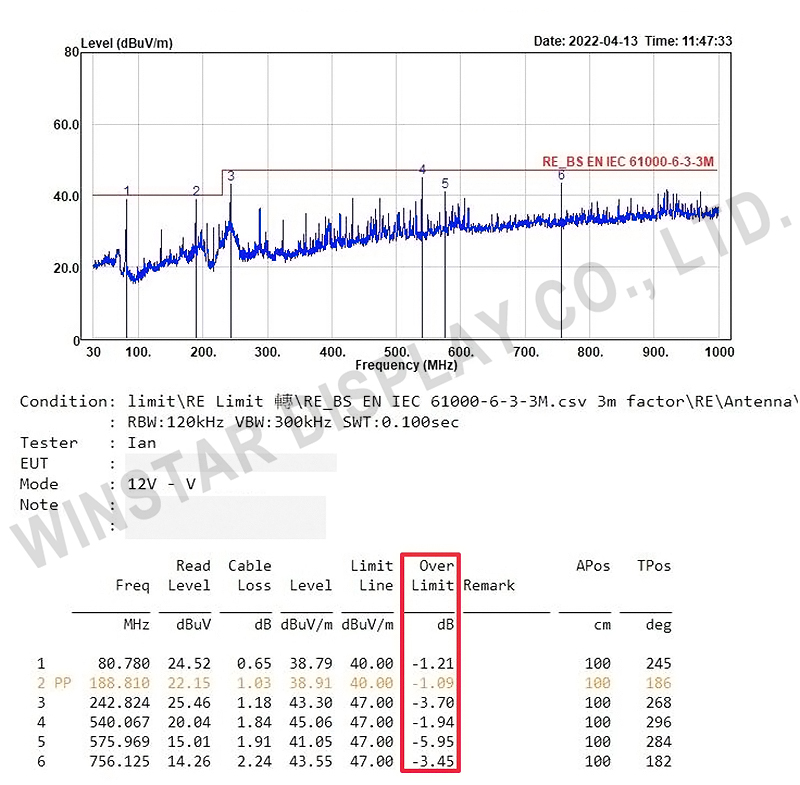

With the interference analysis as above, the solution can be to insert a Ferrite bead in series on the path of the signal to suppress the high frequency harmonics of the signal. To work around the DUT for verification again and we can find a solution to obtain results that pass the EN 55011 standard. The Pre-Scan verification is as follows:

Horizontal

Vertical

Conclusion:

To ensure the quality can meet customers’ requirements. Supplier will conduct the EMI pre-scan after the Smart Display standard model launches and provide the EMI pre-scan report for customer reference so that they can have a better scope of product design with EMC/EMS certification..

Besides, take the above analysis of radiation sustainability, for instance. Supplier can also design & develop products that follow the regulations customer require and meet different market demands of EMC/EMS. Finally, we can make customers’ end products more qualified and secured.